Germany's innovation leader for packaging tape optimization

Increase your packing performance and packing results with innovative and ergonomic tape systems.

We optimize your packaging process

Packing tape

Expertise

Over 40 years of experience in the development of adhesive tape systems.

Ergonomic packing tape systems

75% less strain on the wrist: Two-time ergonomics award winner.

Development of

our own adhesives

Novel adhesives for every application.

Our own tape

testing laboratory

Internal tests according to DIN EN standards.

Packing tape expertise

At the envirogroup, Germany's leading specialists are continuously working to develop new types of adhesives and adhesive tape systems that make our customers' packaging processes easier and safer.

Rely on our experts for all your packing tape needs!

History of adhesive tape system development

2005 Market launch of the Etape system. First compact hand-held tape system with 150 meters on a safety dispenser.

2009 Development of the novel XHT-90® adhesive

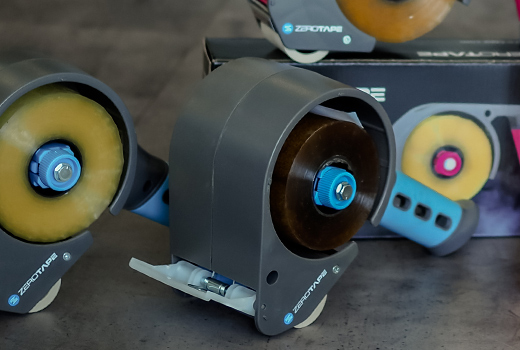

2016 Market launch of the world innovation "ZeroTape" - the first ergonomic packing tape system

2017Development of the new IHB-120® adhesive

2020 Market launch Model II "ZeroTape®"

Ergonomic packing tape systems

Own test laboratory for adhesive tapes

In our in-house laboratory, our technicians professionally test the material properties and quality of adhesive tapes and document them in test reports.

Laboratory tests

We test our own products for quality assurance, but also tapes from our customers' shipped goods. Based on these laboratory tests, we can develop customer-specific product optimizations and increase the security of the closure.

Our standards include:

- Test of tensile strength according to DIN EN 14410/2003

- Adhesive strength according to DIN EN 1939/2003

- Material thickness according to DIN EN 1972/2008

- Refrigeration and freezer tests

- Heat tests

- UV irradiation test

- Long-term stress test

- Adhesion tests on various surfaces

- Comparative tests

Development of our own adhesives

With the in-house development of the XHT-90® and IHB-120® adhesives, we have created the optimum solution for all areas of application. This allows us to look at packaging tape optimization from all angles.

Adhesive XHT-90®

All the positive properties of conventional adhesives can be found in this new type of adhesive. XHT-90® adhesive has, in addition to the high initial tack (property of hotmelt adhesives), a very high aging and temperature resistance (property of acrylic adhesives) and adheres excellently at cold temperatures (property of solvent adhesives).

XHT-90® is optimal for use on almost all cardboard surfaces and also exhibits excellent adhesion in other application situations.

In addition, the adhesive is largely insensitive to UV rays. Particularly in cold and warm temperatures, the adhesive is characterized by its durability and trouble-free usability. The XHT-90® adhesive is thus one of the latest achievements in the packaging sector, which simultaneously reduces costs and improves packaging results.

Adhesive IHB-120®

"Immediate high bond 120 hours under pressure".

Adhesive tapes have to meet different requirements in the packaging process. With IHB-120® we have developed an adhesive that goes far beyond the positive properties of conventional adhesives.

The IHB-120® is particularly suitable for the heaviest packages and guarantees an exceptionally high initial tack. It is used in the food industry, in the frozen food sector as well as for regular parcel shipping over shorter distances. Due to the strong adhesive force, your cartons remain securely sealed until they reach their destination.

The IHB-120® is particularly frequently used on machine tapes.